Automatic Robotic Electric Vehicle Charging Machine With Digital Payment

ABSTRACT

With the rising number of electric and hybrid vehicles the demand for customer-friendly and innovative solutions for the charging infrastructure is growing steadily. Furthermore, future autonomous driving and parking vehicles are calling for new approaches regarding to battery charging. Nowadays electric vehicles have to be charged by hand. In other words, someone has to connect the charging cable with the charging socket of the vehicle. This report deals with automated charging systems for electric vehicles. The major contribution is done by incorporating an Robotic Hand to plug IN / OUT the charging wire to vehicle charging port. Generally, it takes minimum of one hour to charge the vehicle. In order to save the valuable time of customer we incorporated a mobile charging station interface. When charging finishes charging station send notification to the customer mobile that the charging is completed. To support the digital India a private account is provided to the customer per vehicle, when the vehicle enters the charging station with the help of mobile charging station interface, it identifies the vehicle and access its account. A Digital Timer is used to calculate the charging duration, based on the energy tariff the cost of charging is calculated and corresponding amount is debited from that customer account. The transaction details, charging duration time and offers during a day will be available in the charging station service provider site and can be accessed by the personal username and password.

INTRODUCTION

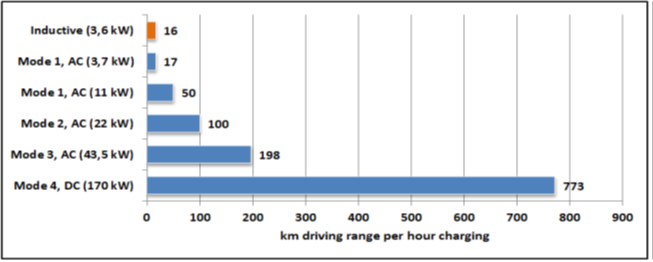

Besides the limited range of electric vehicles in comparison to conventional powered vehicles, one additional drawback is the time consuming and laborious charging process. To enable comfortable and autonomous battery charging lot development effort is invested in inductive charging systems. Due to the advantages of the contactless method, manufactures are working on the market ability of this technique. But several challenges like energy losses, electromagnetic radiation, complex vehicle adaption or environmental impacts on humans and animals still have to be solved. Furthermore, long driving ranges together with short charging intervals are essential for a high customer benefit. Due to a significantly lower power transmission performance, high charging capacities are not feasible with inductive systems, but only with conductive systems (DC quick or fast charging). Battery switch stations provide another option. Because of the high investment costs as well as the difficult grid and vehicle integration these techniques will be not discussed further here. Figure 1.1 depicts how many kilometers per hour loading capacity can be covered depending on the loading method and based on the energy consumption of an average electric vehicle. In this comparison, charge and discharge losses are not considered. As shown fast charging technologies with loading capacities up to 170 kW reduce the charging time significantly in comparison to low charging methods. In order to realize powerful DC charging current the wire diameter must grow. This in turn makes the cable heavy, stiff and unhandy, so that people might have problems to charge their vehicle. This possibility to load vehicles as user friendly as possible is one reason why automated conductive charging systems are getting increasingly interesting. This is what led us to shift our focus towards the greatly and rapidly developing field of Autonomous Electric vehicle charging system and make our academic project related to this particular topic. The project focuses on three main things firstly making large amount of time the drive has to spent for charging the Electric/Hybrid vehicle efficiently. Secondly number employees are required for operating the charging stations by making it fully automated. Finally the traditional liquid cash/card payment system has been transferred to digital payment system. Taking this into consideration the concept of Automated Robotic Electric vehicle charging machine with digital payment struck us. The Automated Robotic Electric vehicle charging machine with digital payment is one such system that solves the above mentioned problems. It has a Robotic hand for plug IN / OUT the charge wire from the vehicle. The robotic hand is a servo mechanism, which uses three servomotors for the movement of arm in three particular direction forward and backward. The charging station has provided a particular account for the vehicle owners to deposit money, so that they don’t have to pay money at the charging station. Based on the consumed energy that much amount of money will be debited from that account. We also developed a mobile charging station interface to communicate with the driver to inform the status of charging, energy consumed bill transaction history and offers in charging rates. We were successful in developing the working prototype, high sensitivity sensors are required for precise identification of charging port in the vehicle irrespective of the position of the car. The Future area of Research and Scope is the addition of a high resolution camera and image recognition sensor to identify the charging port more precisely that make the plug IN/OUT more quickly. It can also be made available in existing petrol pumb with little modifications. So, the aim of this project is to develop a Automated robotic electric vehicle charging machine which help the people to saves their valuable time while charging and support central government digital India project by making the energy consumption bill digitally and eliminating employees for the operation of charging station with the help of Robotic Hand.

II. PROPOSED SYSTEM

The concept proposal is capable to charge any electric car independently from the brand and the charging socket position. It does not require complex vehicle adaptions or modifications. Furthermore, it is possible to charge multiple vehicles with only one robot.

Here, we are using cheap and simple robot charging machine without camera system for locating the charging port and also we incorporated a autonomous digital payment system.

A. MATERIALS

- Servo motor:MG995

- Node MCU:ESP8266

- Battery charge protection for Li-ion:TP4056

- Ultrasonic sensor module:Hc-Sr04

- IR Sensor

- 3D Printed Robotic ARM

- Relay:5V 10A

- Toy Car:RC

- DC Power Supply:7.5V,2A

B. METHODOLOGY

Electric/Hybrid Plug IN vehicle enters the charging station ,Here we are using a RC Toy car as the vehicle .we also arranged a stopper on the floor ,So that the vehicle tyre should park exactly by hitting on the stopper .This arrangement helps the robotic hand enough data to locate the charger port position.

There is a indicator light in the charging station to show whether the charging station is free .we are using IR sensor for this purpose .when the charging station is empty the indicator lights show green ,when vehicle enters the IR sensor transmitted light reflect back by hitting on the car body and it will be captured by the receiver and turns the indicator light red and the charging station becomes active for charging.

The driver pair their mobile with the charging station by login to the web application provided by the charging station and select the charging slot .Once they are paired the charging station gets the details of that car such as the car model ,height of the charging port ,length and breadth wise distance from stopper pad to the charging port .we also use ultrasonic distance sensor to get real time distances.

Based on the above informations robotic arm place the charging wire at the tip exactly to the charging port .we use a magnetic head charging port ,So that the Plug IN of the arm will made more accurate.

The driver pair their mobile with the charging station by login to the web application provided by the charging station and select the charging slot .Once they are paired the charging station gets the details of that car such as the car model ,height of the charging port ,length and breadth wise distance from stopper pad to the charging port .we also use ultrasonic distance sensor to get real time distances.

Based on the above informations robotic arm place the charging wire at the tip exactly to the charging port .we use a magnetic head charging port ,So that the Plug IN of the arm will made more accurate.

After Plug IN the Relay coil gets energised and current is passed for charging .Here we use TP4056 batter charge protection for Li-ion in the car for indicating the charging is taking place .Once the relay coil is energised the timer starts and stops until charging is finished or the driver stops the charging process by clicking stop button through the online web application.

Once the timer stops ,the Relay will be de-energised and the robtic arm will be withdrawn to intial position .Based on the charging time ,Node MCU ESP8266 calculate the bill and send to the charging station server through wifi hotspot .This amount will be debited from the account of the driver provided by the charging station company .Above transaction details will be accesable to the driver by login to their web portal.The above proposed system is shown in Figure 4.

DISCUSSION AND OUTLOOK

The main idea of automated charging systems includes a very easy and comfortable charging process. The car parks in the parking bay and the remaining steps are being finished by the system automatically. That means the automated charging system detects the type and model of car, recognises thereupon the position of the charging socket, the required charging cable and charging strategy and starts afterwards with the charging process. As soon as the process is finished, the system picks up the charging cable and the vehicle is ready to drive. But there are some obstacles that need to be adjusted in order to realize automated conductive charging. From a purely technical point of view, such systems seem to be state of the art, but there are some challenges that must be solved - and for the target to handle different vehicle types, the challenges are rising significantly.

There is no standard for the position of the charging socket. An investigation of various vehicle types shows big differences regarding the socket places depending on the car brand and type. Electric and hybrid vehicles usually have their sockets on the right or left side, additionally some cars have it on the front or back side of the vehicle. Furthermore, the height of the socket is also different. There is a European standard for charging cables, the Type 2 (Mennekes) connector, but many manufacturers, especially in Asia or USA use other connector types.

A second big problem can be found in the charging cap mechanism. Several vehicles have a security cap that makes it impossible to charge the vehicle without removing them. Even in this field there are differences. Some brands have a rubber plug which has to be unscrewed, others have a plastic flap. The variety of the systems is often simply based on specific design solutions.

The target to charge multiple vehicles and different vehicle types at parking facilities requires complex devices for handling and management of cables, especially by the use of DC quick charging. Long and heavy cables with limited bend radius waste a lot of space and additionally, if they are not carried by the robot, separate logistic equipment is needed. For example, the weight of a CCS-Type 2 charging cable for charging capacities of up to 106,25 kW is 1,7 kg/m and it has an outer diameter of 28,2 mm.

An overview about the proposed vehicles charging socket is presented in Figure 5 shows a typical parking situation of vehicles including the resulting charging socket position. As mentioned, these varieties of systems and vehicle-specific requirements complicate an automation of the charging process enormously.

LITERATURE SURVEY

Automated robot-based charging system for electric vehicles

Volkswagen e-smart Connect

Tesla charging-robot

Charging system TU-Dortmund

Charging system NRG-X

Automated charging systems are in development this time, but no manufacturer has launched a series product on the market until now. Furthermore, every current published system is only customized for one specific vehicle model. That means that only that specific model can be charged. In future years an automated system should be able to charge every electric vehicle independent from the car type.

The manufacturer VW recently presented such a system for an e-Golf, as a research facility in the test phase. The project, shown in Figure 2.1, is called e-smart Connect and is based on a KUKA LBR, a Robot of the newest generation. The DC quick charging process starts with a communication between vehicle and electric filling station. The vehicle transmits its data to the charging station, which transmits in return the target position for the automated parking. The charging socket of the vehicle has to be in a target area of 20 by 20 centimeters. Afterwards, a camera on the robot detects the exact position of the charging socket, which is accurately defined to a millimeter. Following, the robot-gripper picks the DC-Connector and links it with the charging socket of the vehicle. After having linked the DC-Connector, the charging process starts. Once the battery is fully charged, the robot automatically unplugs the DC-Connector.

The US Company Tesla also works on an automated system (Figure 2.2). Their concept is even based on DC current and should load their on-site vehicles. The charging cover opens automatically when the parked vehicle is ready for loading. The system detects this and afterwards the snakelike prototype robot arm is searching its way to the charging socket fully autonomously. Once the connection between the robot and the vehicle is made, the charging process can be started. The idea behind the concept is, that the driver does not have to get out of the car to charge the vehicle. The complete loading procedure is applied by the robot. How the robot finds its target and detailed technical information about the charging system are not published yet. In general, the system is currently in a prototype status this time. A benefit of Tesla is that all their cars have the same position of the charging socket and also the same charging plugs

The Technical University of Dortmund started a project named Alane. The acronym stands for automated charging system for sustainable electric mobility (Figure 2.3). The aim of the project is to charge a parked electric vehicle without needing the driver to plug in the charging cable. A manual intervention of the driver is not necessary. Thus, in comparison to established charging systems, the Alane system raises the comfort enormously, which represents itself as a unique selling point in comparison to conventional powered vehicles. The charging system of the TU Dortmund contains a standard energy supply and a wall box, which is extended with a cost-effective and compact connection module (VBM). The connection and disconnection process can be started via a smartphone app. This system is also in a prototype status yet and under further development.

The NRG-X concept represents itself as the first fully automatic charging solution. The fundamental idea was to create a system, which transfers high power energy for fast charging, enables a great range of parking tolerance and substitutes an expensive conventional wall box. Additionally, it can be easily adapted to every electric vehicle. The system shown in Figure 2.4 contains two basic components, a connection array, which is mounted in the middle of the car underbody and a base station, which represents the connection system at the parking area. The surface of the connection array is consistently structured by a hexagonal pattern, whereas each cell has a conical shaped recess. The base station, which constitutes the counterpart, slides into any cell by an orthogonal movement towards the connection array. This means, any arbitrary position of the cone within the dimensions of the connecting array reaches a discrete final position in the middle of the respective contacting cell. The positioning cone must be resilient and therefore laterally (in x- and y-direction) moveable for the distance of a contacting cell outer radius. The hole charging process is quite simple: When an electric vehicle, which is adapted with the NRG-X connection array, approaches to a garage or parking space, the NRG-X base station automatically starts to communicate with the connection array. The only requirement is that the electric vehicle must contain a wireless module. It is not necessary to park the vehicle in an exact predefined position. A position validation system ensures the correct position where an automatic connection is feasible. After the system checked the authorization and the batteries state of charge, the charging process starts automatically. The NRG-X base station lifted upwards to the connection array of the car underbody and connects the system. Possible charging power reaches up to 22 kW. The charging process starts automatically when a secure connection is enabled or can be scheduled manually or by an intelligent charging management system. If the battery is completely full, the connection system disconnects immediately and automatically. In a further expansion stage, direct current quick charging should be realized above >100 kW.

WORKING

Electric/Hybrid Plug in vehicle enters the charging station, here we are using a RC Toy car as the vehicle. We also arranged a stopper on the floor, so that the vehicle tire should park exactly by hitting on the stopper. This arrangement helps the robotic hand enough data to locate the charger port position. There is a indicator light in the charging station to show whether the charging station is free. We are using IR sensor for this purpose. When the charging station is empty the indicator lights show green, when vehicle enters the IR sensor transmitted light reflect back by hitting on the car body and it will be captured by the receiver and turns the indicator light red and the charging station becomes active for charging. The driver pair their mobile with the charging station by login to the web application provided by the charging station and select the charging slot. Once they are paired the charging station gets the details of that car such as the car model, height of the charging port, length and breadth wise distance from stopper pad to the charging port. We also use ultrasonic distance sensor to get real time distances. Based on the above informations robotic arm place the charging wire at the tip exactly to the charging port. We use a magnetic head charging port, so that the Plug IN of the arm will made more accurate. After Plug IN the Relay coil gets energized and current is passed for charging. Here we use TP4056 batter charge protection for Li-ion in the car for indicating the charging is taking place. Once the relay coil is energized the timer starts and stops until charging is finished or the driver stops the charging process by clicking stop button through the online web application. Once the timer stops, the Relay will be de-energized and the robotic arm will be withdrawn to initial position. Based on the charging time, node MCU ESP8266 calculate the bill and send to the charging station server through wi-fi hotspot. This amount will be debited from the account of the driver provided by the charging station company. Above transaction details will be accessable to the driver by login to their web portal.

FUTURE CONCEPT PROPOSAL

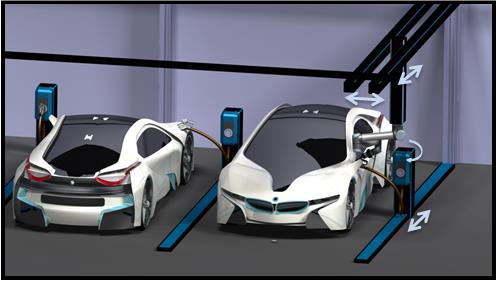

The basis of the concept is a lightweight collaborative robot that is mounted on a bridge crane-like system. This approach increases the range of motion for the robot significantly every charging station spot is reachable and the number of cars is only limited by the length of the crane system. Safety plays an important role when using robots. Safety features of the robot allow people to be in the same working area as the robot and no safety fence is needed (collaborative robots). Force torque control enables well contact detection as a programmable resilience. Furthermore, the plug-in process is precise and force sensitive. Companies like Universal Robots or KUKA offer such robots.

Every parking lot is equipped with a longitudinal movable and rotatable cable magazine, which travels closely to the charging socket before the charging process begins. This prevents sliding on the ground as well as difficult handling of heavy and long cables. With a universal gripper tool mounted on the robot arm, different types of charging plugs can be picked up from the cable magazine. If a vehicle has to be charged, it parks in a free parking lot (manually or autonomously). For the next steps and for a successful charging process, the system must gather important data, including information of the already discussed variety of systems in the subsection problem areas. With wireless interconnectedness of vehicle, electric filling station, mobile phone and web servers, the charging process can be started or stopped as well as vehicle and charging strategy data can be transmitted and updated. The easy integration of billing and payment applications and storing and evaluation of the costumer charging behavior improves costumer benefit additionally. Figure 10 shows a proposal for the data communication and the data management of an auto-mated electric filling station in public areas.

After the required information is transmitted, it is possible to control the charging process and the battery’s state of charge. Meanwhile the vehicle is charging, the robot can serve other vehicles that also need to be charged. When the charging process is finished, the robot disconnects the

cables and puts it back into the magazine and the whole process can start again from the beginning.

CONCLUSION

Conductive automated charging systems are a new emerging topic in the electric vehicle industry. By increasing charging power, the cables are getting more unwieldy and thereby charging of a vehicle can be very aggravating. Some pilot projects already employ with automatic charging systems, but currently they are all in a prototype status. The presented concept of an automated charging robot for parking garages gives an overview of possibilities for possible solutions. It considers the importance that every electric vehicle can be charged by one system. Furthermore, there are no modifications to the vehicle necessary. Future electric cars will be designed for automated charging. This includes barrier-free access to the charging socket or automated opening and closing systems of the loading covers and standardized communication systems. Inductive charging systems will be an alternative, but disadvantages like the limited charging capacity or unstandardized systems may restrict the application to private sector usage. Conductive automated charging systems include a high potential, whether in private or public sectors, to make charging of electric cars more comfortable.